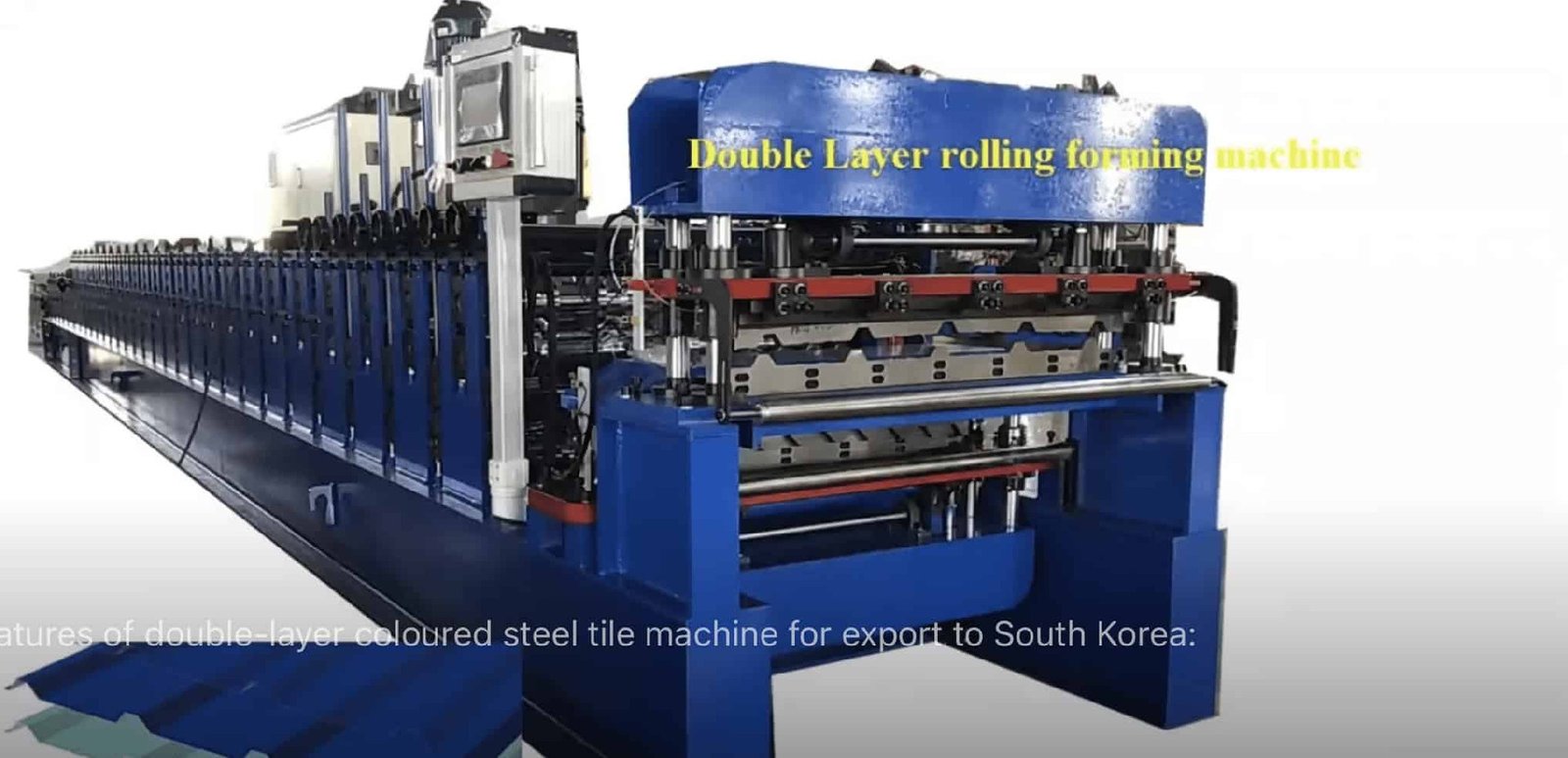

Double Layer Roll Forming Machine for South Korea

The double layer roll forming machine is engineered to deliver exceptional performance, energy efficiency, and adaptability for the South Korean market. Designed with smart switching capabilities, advanced motor systems, and versatile material compatibility, this equipment offers a cost-effective and eco-friendly solution tailored to South Korea’s building materials industry. Whether for roofing tile production or high-end laminated steel panels, this system ensures operational efficiency while maintaining compliance with local energy standards.

I. Smart Dual-Layer Switching System

Independent Dual-Layer Operation

At the heart of the machine is a dual-layer independent switching mechanism, controlled via an intuitive PLC system with a responsive touch screen interface. Users can freely switch between single-layer and dual-layer operation modes depending on production needs. When operating in single-layer mode, the system reduces unnecessary mechanical engagement, saving between 30% and 50% in energy consumption.

High-Precision Brake Motor

A built-in servo motor with integrated electromagnetic brake ensures lightning-fast response during layer transitions or emergency stops. The braking response time is under 0.1 seconds, significantly reducing material wastage during unexpected halts and enhancing overall process control.

II. Advanced Material Compatibility Features

Adjustable Pressure Roller System

This double layer roll forming machine incorporates an adaptive pressure roller setup with a wide range of adjustable pressure (0–20 MPa). It seamlessly handles various coil types, including standard colored steel coils (0.3–1.2mm) and pre-coated or laminated steel materials. The system includes anti-scratch roller coatings to prevent surface damage during forming, preserving the aesthetic integrity of the final product.

Optional Thermal Control for Coated Coils

An optional temperature control module supports a low-temperature forming mode (80–120°C), specifically designed for sensitive coated materials. This feature helps prevent thermal degradation of the membrane layers, especially important when working with specialty construction-grade coils used in South Korea.

III. Energy Efficiency and Eco-Friendly Configuration

MEPS-Compliant IE4 Motor

The equipment features an IE4 high-efficiency motor, compliant with South Korea’s MEPS (Minimum Energy Performance Standards). Compared to conventional motor systems, it delivers up to 15% energy savings, reducing both operating costs and environmental impact.

Automatic Low-Power Standby Mode

To further enhance energy performance, the machine includes a low-consumption hibernation mode. If the system remains idle for more than 10 minutes, it automatically shifts to standby, consuming only ≤50W of power — a feature especially valuable in intermittent production environments.

Optional Waste Collection Unit

An optional waste recycling device can be integrated for automated collection and compaction of edge trims or leftover materials. This not only supports cleaner workshop environments but also promotes responsible material reuse in compliance with modern sustainability expectations.

IV. Key Competitive Advantages in the South Korean Market

Fast Layer Switching = Higher Output

Compared to traditional systems that require up to 15 seconds to switch between layers, our machine achieves this in under 5 seconds. This improvement results in approximately 20% increased production capacity, making it a strong contender in high-output manufacturing lines.

Support for Second-Hand Coil Usage

The system is designed to be compatible with second-hand colored steel coils, allowing users to reduce material costs without compromising product quality. This helps lower procurement thresholds, particularly beneficial for small- and medium-sized manufacturers seeking cost-effective operation.

Customization for High-End Finishes

A customizable UV laminating module is available to meet the demand for premium surface finishes, particularly in South Korea’s competitive architectural materials segment. This makes the machine suitable not only for standard roofing sheets but also for decorative panels used in high-end residential and commercial projects.

V. Strategic Fit for the South Korean Market

This double layer roll forming machine is tailored to meet the exacting standards of South Korean manufacturers. From its compliance with energy regulations to its smart automation and material compatibility, it stands out as a future-ready solution for producers aiming to reduce costs while improving output quality.

To further localize the system, we recommend collaborative material adaptability tests with South Korean partners. By doing so, manufacturers can ensure a perfect match between the machine’s forming capabilities and the specific coil materials favored by end-users in the region.