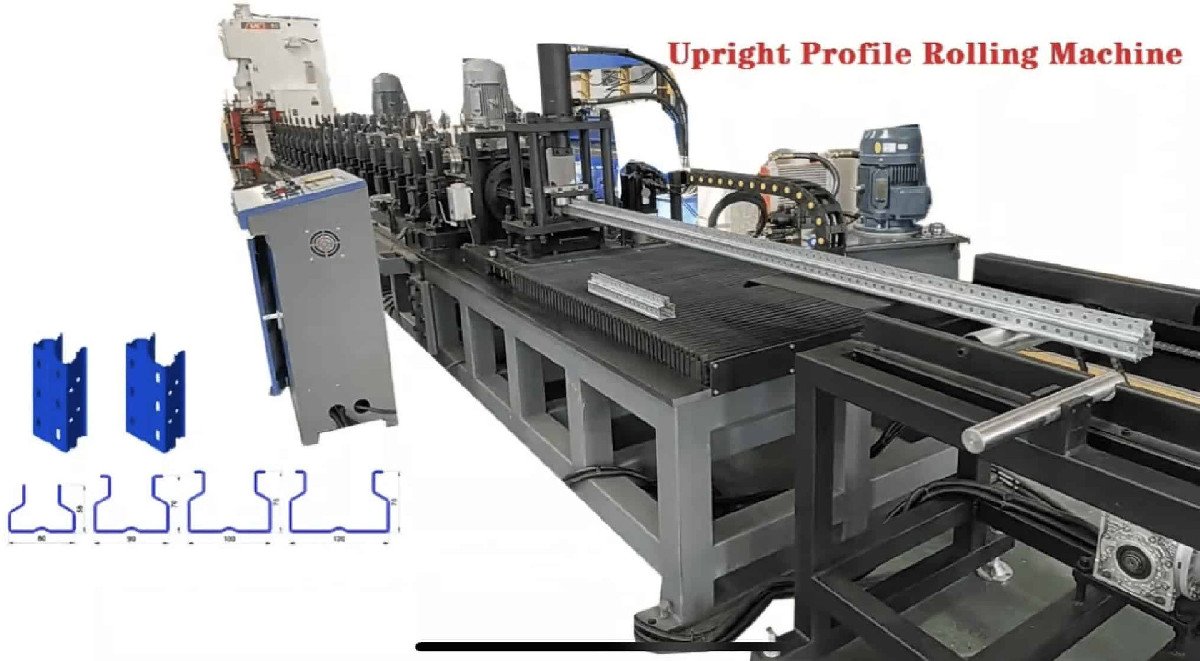

Upright Rack Profile Making Machine: High-Efficiency Solution for Industrial Storage Systems

The Upright Rack Profile Making Machine is a specialized roll forming solution designed for manufacturing upright rack profiles used in warehouse storage systems. These machines are essential in producing vertical support structures — commonly known as upright columns or uprights — which serve as the core framework in pallet racking and shelving systems. With capabilities to produce various shapes such as L-type, standard C-type, and reinforced heavy-duty C-types, this equipment ensures high production efficiency, dimensional accuracy, and structural strength to meet the needs of modern logistics and warehousing.

I. Introduction to Upright Rack Profiles

Upright rack profiles are fundamental components of pallet racking systems, supporting the entire vertical load of stored materials. Depending on the intended load capacity and application environment, these profiles come in different configurations:

L-Shaped Uprights: Typically used for light-duty storage systems, these profiles offer sufficient support while minimizing material usage.

C-Shaped Uprights: Designed for medium-duty applications, balancing strength and cost-effectiveness.

Heavy-Duty C Profiles: Manufactured for high-capacity storage needs, often with steel thicknesses of up to 2.5mm to handle significant vertical loads.

To allow the integration of load beams and shelving components, these uprights include precisely punched holes and slots — such as tear-drop holes or other standardized patterns — that ensure easy assembly and compatibility with various storage systems.

II. Overview of the Upright Rack Profile Making Machine

The Upright Rack Profile Making Machine is engineered to automate the forming process from raw steel coil to finished rack profile with punching, cutting, and forming integrated into one continuous production line. It provides:

Customizable profile shapes and sizes according to customer specifications

Automated punching for various hole designs (tear-drop, square, oval, round, etc.)

Adjustable roller stations to accommodate different material thicknesses and profile dimensions

High-speed forming with minimal manual intervention

III. Key Features and Technical Advantages

1. Versatile Profile Formation

This roll forming system supports multiple profile types and sizes with tool-change capability. Whether producing light L profiles or thick heavy-duty C shapes, the machine delivers precise and consistent output with minimal deviation.

Material thickness range: 0.8mm to 2.5mm

Profile width: customizable up to 120mm or more

Compatible with galvanized, cold-rolled, or hot-rolled steel

2. Integrated Hole Punching System

Punching is synchronized with the roll forming process using a servo-feeding and hydraulic punching system. This ensures:

High punching accuracy

Customizable patterns such as tear drop, oblong, and slot holes

Smooth edges without burrs, reducing post-processing requirements

3. Strong Structural Design for Heavy Loads

The Upright Rack Profile Making Machine is built with a reinforced base, durable roller shafts, and industrial-grade forming stands, ensuring long-term stability even during high-volume production of heavy gauge materials.

4. PLC-Controlled Automation

Equipped with an advanced PLC + HMI control system, the operator can easily set production parameters, monitor machine status, and switch between product specifications. The interface supports:

Recipe memory for multiple profile types

Real-time diagnostics and error alerts

Remote support (optional)

5. High-Speed Production Efficiency

With forming speeds of 10–15 meters per minute, this machine is ideal for high-output operations. Optional flying shear cutting units further increase efficiency by eliminating the need for line stops during cutting.

IV. Applications in Storage and Logistics Industries

Profiles produced by the Upright Rack Profile Making Machine are widely used in:

Industrial pallet racking systems

Retail shelving frameworks

Automated storage and retrieval systems (AS/RS)

Mezzanine support structures

Cold storage rack systems

Due to its flexibility, the machine serves manufacturers targeting diverse industries, from warehousing and logistics to retail and heavy manufacturing.

V. Customization Options

To meet specific market or client requirements, the machine can be tailored with:

Multiple punching dies for varying hole patterns

Servo-driven cutting systems for smoother profile ends

Automatic stacker and collection units

Quick-change tooling system for reduced downtime

For international clients — including those in Europe, the Middle East, and Southeast Asia — machine configurations can be adapted to local electrical standards and safety regulations.