Advantages of C Purlin Roll Forming Machine

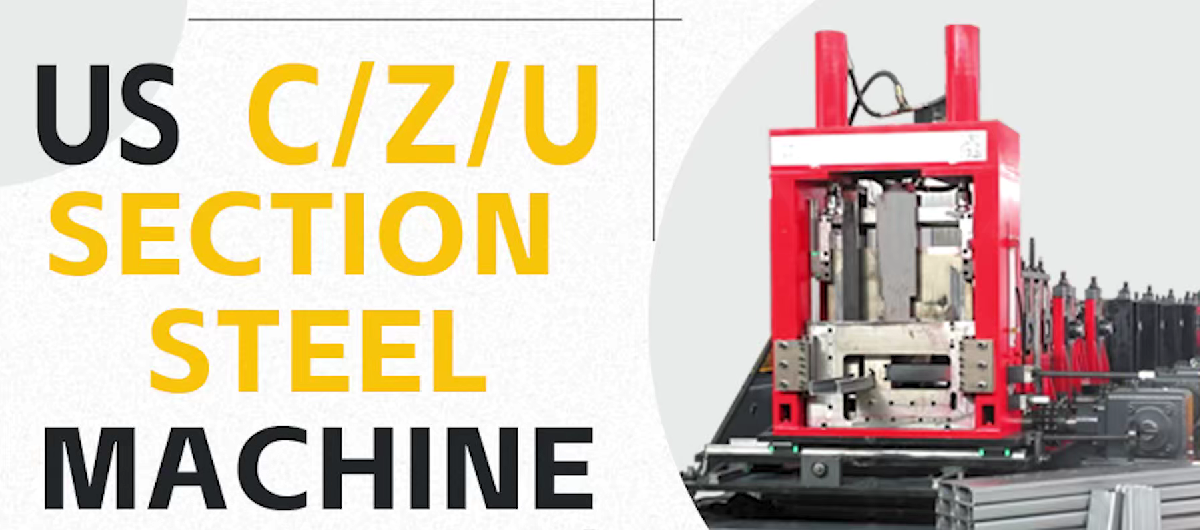

CZ steel purlins, produced through cold roll forming processes, offer high-quality, standardized, and optimized steel shapes widely used in steel structure projects. The C purlin roll forming machine is a key player in producing these versatile shapes. It effectively processes hot-rolled steel coils or strips into distinct "C" and "Z" profiles with precision, using advanced PLC system control.

The C purlin roll forming machine operates with a high level of automation, ensuring efficiency and consistency in production. Through multiple stages of rolling, the machine forms C and Z-shaped purlins, with the system capable of fine-tuning angles and radii to create accurate products. Additionally, it features quick production mode switching based on preset parameters, significantly boosting both production efficiency and product accuracy.

The machine's material specifications are standardized, with a typical thickness range of 1.5mm to 3mm and a width of 200mm to 600mm. The stable structure of the C purlin roll forming machine is built on a frame system, designed to improve machine stability. This structure, which incorporates both C and Z profiles, effectively reduces vibrations and pressure during operation, enhancing overall machine performance.

Compared to traditional machine structures, the frame construction of the C purlin roll forming machine enhances its resistance to deformation by over 40%. This ensures stable performance even at high speeds, minimizing machine shake and misalignment. With precise control from the PLC system, the machine reduces dimensional errors, ensuring high product accuracy.

High-Speed Production and Customizable Output

One of the most notable features of the C purlin roll forming machine is its ability to maintain a consistent production speed of 25 to 40 meters per minute. This speed can be automatically adjusted based on the thickness of the material being processed. For thicker materials, the machine slows down to maintain optimal forming quality. Conversely, when processing thinner materials, the speed increases, boosting output without compromising quality.

The feeding section of the machine incorporates advanced features such as "one drag, one press" control, which prevents material from jumping or shifting during feeding. This system, combined with a leveling device, ensures the material enters the production line evenly and remains stable, preventing material deformation and ensuring smooth processing.

Precision Material Handling

To avoid material twisting or misalignment at the entry point, the C purlin roll forming machine is equipped with trimming wheels. These wheels help ensure that materials stay flat and aligned, providing better control over material movement during the forming process. The trimming wheels are made from high-strength alloy steel and are adjustable to accommodate various material sizes.

As the material moves through the entry section, the trimming wheels apply consistent lateral pressure, guiding the material into position while eliminating minor imperfections like waviness or edge curling. This dual-function design helps maintain precision in the material's shape and ensures its smooth progression through the forming process.

Rollers: The Heart of C Purlin Production

The key to producing high-quality C purlins lies in the machine's rollers. These rollers progressively shape the material from a flat sheet into the desired C-profile, ensuring each part of the process is meticulously controlled. Different rollers are designed for specific tasks, such as initial bending or fine adjustments, to create the perfect C shape.

Precision in roller alignment is crucial. Any deviation in roller positioning could result in dimensional errors, negatively affecting the finished product. By using accurate rollers, the C purlin roll forming machine guarantees the correct shape and reduces the likelihood of defects in the final steel profile.

Conclusion

The C purlin roll forming machine stands out in the market for its ability to produce high-quality, precise C and Z purlins at fast speeds. With robust construction, advanced automation, and a focus on reducing operational costs, this machine is the ideal choice for manufacturers looking to optimize their steel structure production processes.

By ensuring stable material handling, high-speed production, and precision shaping, the C purlin roll forming machine provides significant improvements in both efficiency and product quality. Whether you are working with thick or thin steel, this machine delivers consistent, reliable results, making it a must-have for modern steel fabrication.