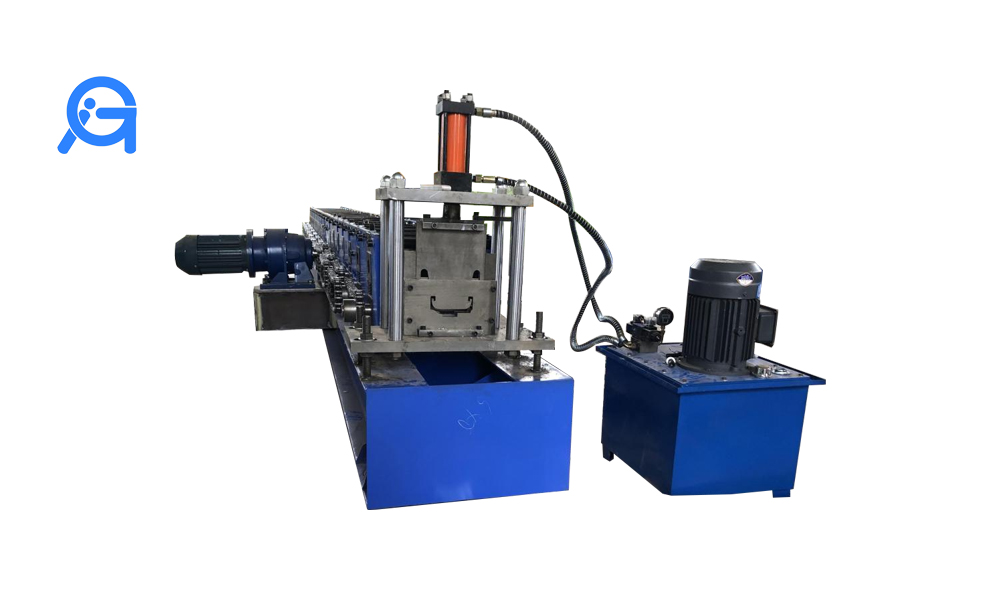

Double layer roofing sheet roll forming machine

Double layer roofing sheet roll forming machine has two layers.The double layer roll forming machine combines the two models together, with reasonable structure and beautiful appearance. It has the characteristics of saving space and simple operation, and is especially suitable for customers with small sites and on-site construction.

1.General Information of Equipment

The specifications of the Double layer roll forming machine

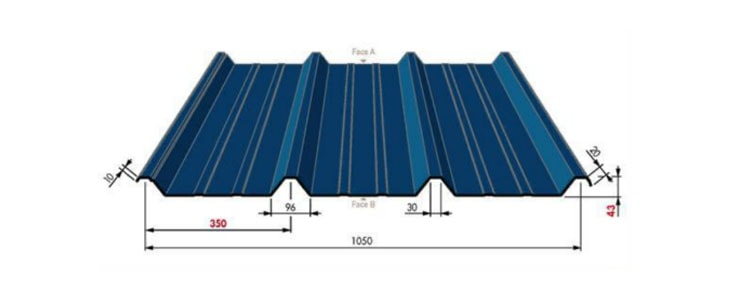

Profile drawing(we can design as customer's profile drawing):

Raw material of the coil: PPGI,PPGL,GI,GL

Coil thickness:0.5mm

Coil width:1250mm

Forming machine Dimension: around 9500*1650*1800mm

Cutting length:adjustable

Total power: 9.5kw

Work voltage: 380V, 60Hz, 3Phase( or as your requirement)

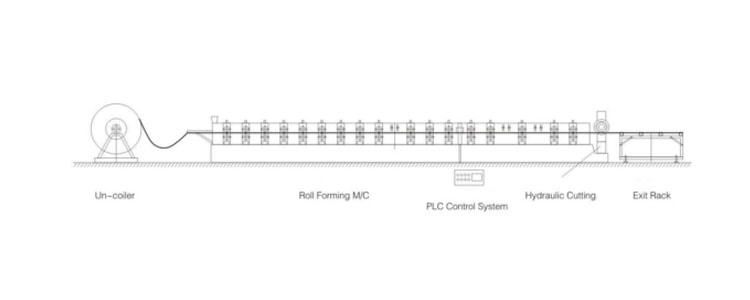

2.Working flow

Decoiler----Rolling Forming---Cutting system ---Products receiving table

3.Machine parts details

3.1Decoiler

We have two types of the decoiler you can choose.

A.5 tons manual decoiler

Work type: passive type

Structure:steel channel welded for basic frame

Usage:to support the coil and make the uncoiling

Loading capacity: 5 tons

Inner diameter:450-550mm (manual adjustment)

Coil width:1200mm

Brake system:manual brake

B.Hydraulic decoiler with trolley

Loading capacity:5 tons

Inner diameter:450-550mm

Coil width:1250mm

Driving motor power:4kw

Hydraulic motor power:4kw

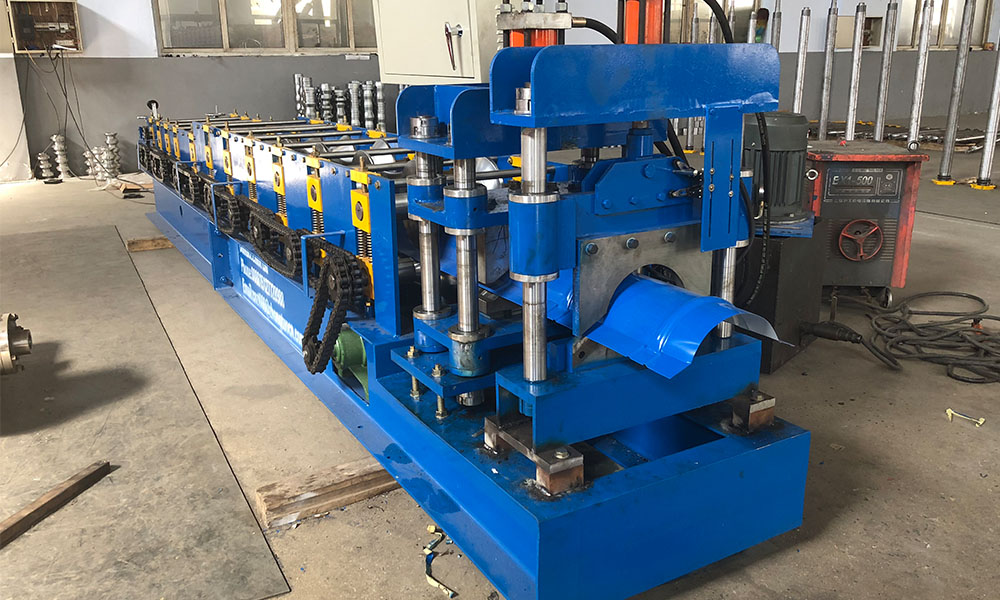

3.2main roll forming machine

Feeding device:One set guiding roller, Steel plate welded platform to carry the sheet and feed into roll forming system

Rolling shaft: Material 45#, Shaft diameter 80mm; fine processing

Roller: 45#, fine processing

Work speed: 15-20m/min

Machine structure: middle steel plate welded structure, plate thickness 20mm

Machine basic frame: 350H beam welded

Main motor power:5.5kw

Rolling spacer:Anti rusty treatment

Transmission:by chains, please note fill the lube in case the chains getting dry

3.3cutting system

Work type: Hydraulic cutting

Cutter material: Cr12 quenched

Cutting length tolerance:±1mm

Use 4 columns, more stable when machine working

3.4PLC control station

Frequency brand: Delta brand (original)

PLC brand:Delta brand (original)

Low pressure electric part: Schneider brand

Encoder: Omron brand

Screen type:Touch screen,also have bottons on the panel

Cut command:Yes

Profile length set-up:Yes

Bacth quantity program:Yes

3.5 Hydraulic station

With cooling fan or not :Yes

Hydraulic motor power:4kw

Hydraulic oil: 46# hydraulic oil

Oil tube and wires connection:All the tubes and wires will be marked by the numbers or letters, so that it will be very easy to connect for the new

3.5Receiving table