High Speed Glazed Roof tile Roll Forming Machine

Glazed roof tile roll forming machine can produce different profiles of glazed roofing sheets in various thickness and colors.

Glazed tile roofing sheet is a new type of building material. It uses color steel plate as the base plate and is formed after special processing and special baking. It has light weight, high strength, good water resistance, convenient and fast installation, and can be widely used in villa roofs, urban flat-to-slope conversion, tourist scenic spot buildings, etc.

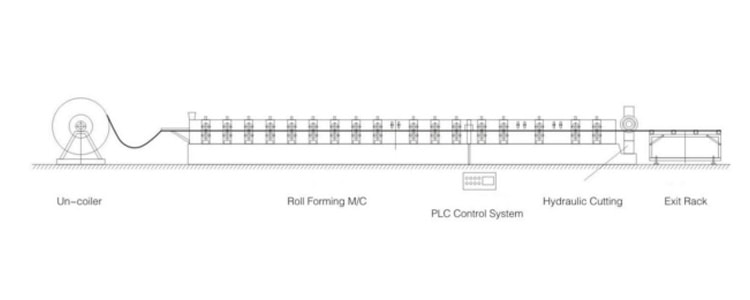

1.Working flow of Glazed Roof tile Roll Forming Machine

Decoiler--Main Roll Forming Machine--Hydraulic Shearing--Collecting Product Table

2.Technical specification

Decoiler Type: Hydraulic power

Working Type: Active Type

Loading Capacity: 10 Tons

Coil Inner Diameter: φ450-700mm(Adjustable)

Coil Outer Diameter: Max. φ1500mm

Coil Width: Max. 1250mm

Loading Power: 1.5 kW

Driving Power:3 kW

Hydraulic Power: 5.5 kW

With brake system

Uncoiling Speed: 0-60 m/min

Speed: 0-8 m/min ( 500 tons/month )

Main Forming Motor Power: 5.5 kW, 460V/60Hz/3Phases

Machine Frame: 400# H-beam Steel Welded With Support

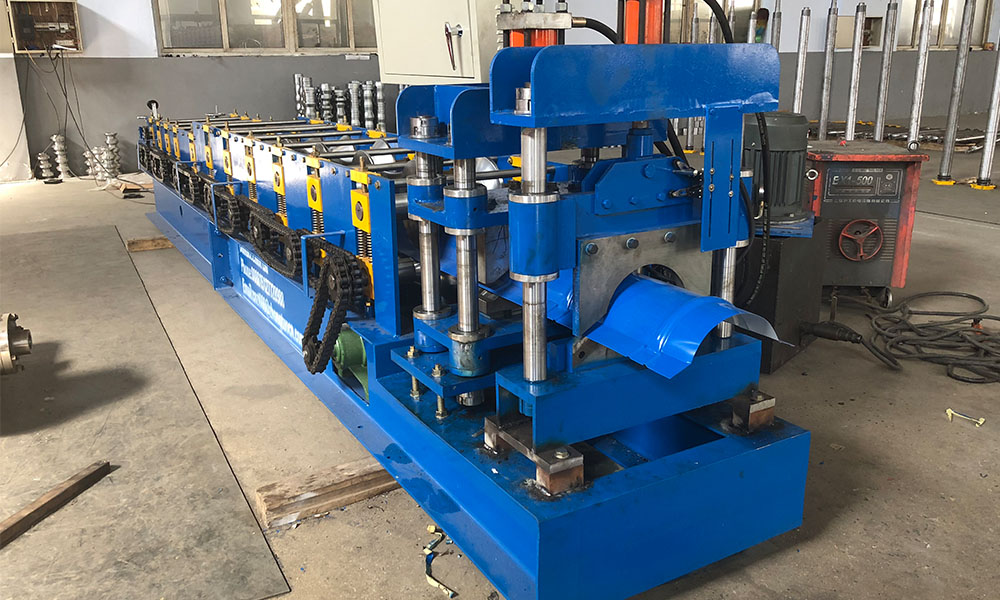

Roller Shaft: φ80mm Solid Shafts, 45# Steel Tempering

Roller: 45# Quenched, Surface Hard Chromium Plating

3.Components of Glazed Roof tile Roll Forming Machine

Part 110T Hydraulic Decoiler With Loading Car

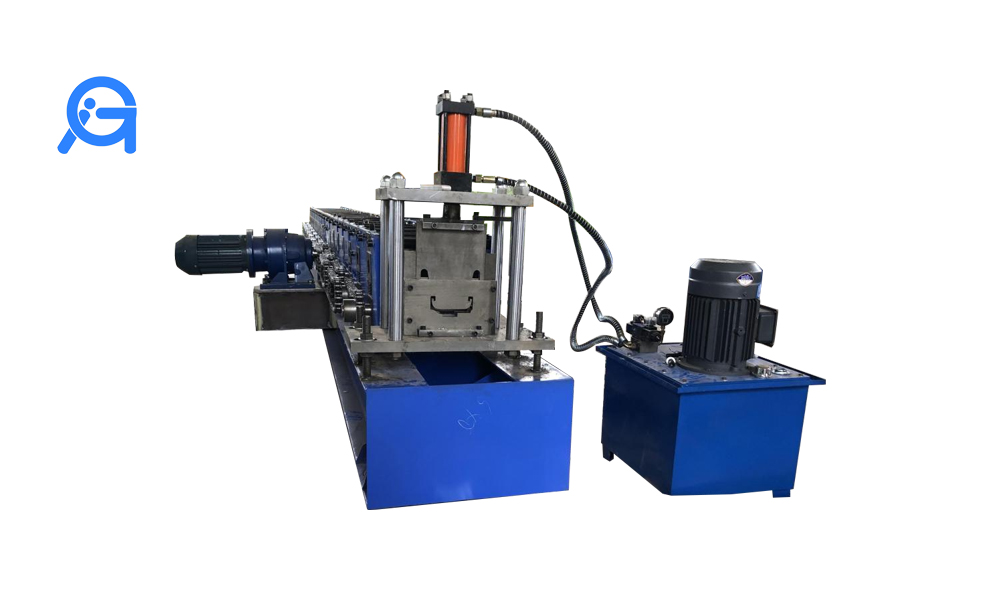

Part 2Main Roll Forming Machine

Part 3PLC Control System

Part 4Hydraulic Station

Part 512m Automatic Stacker

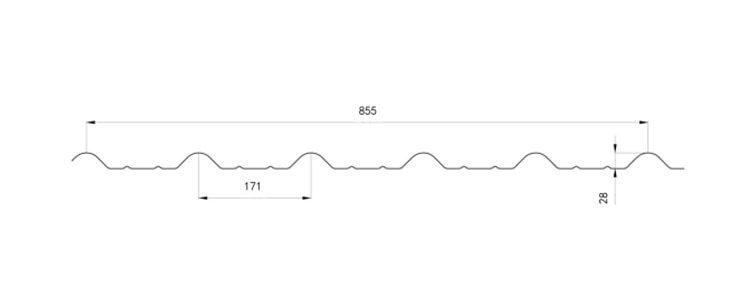

4.Profile drawings

(we can design as customer's profile drawing)